constant environment unit for greenhouses

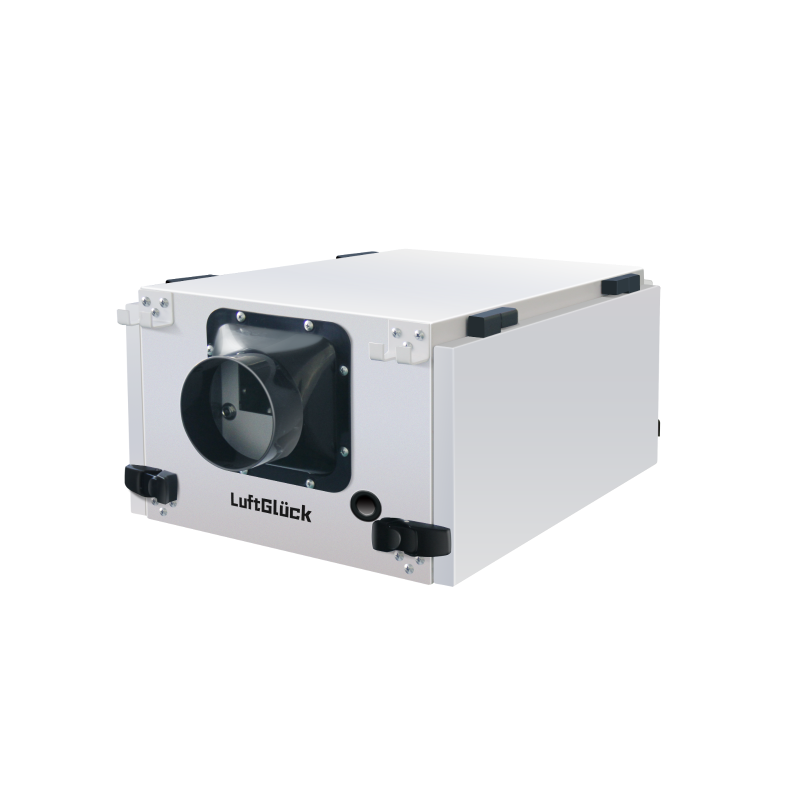

A constant environment unit for greenhouses represents a cutting-edge solution designed to maintain optimal growing conditions for plants throughout the year. This sophisticated system integrates multiple environmental control mechanisms to regulate temperature, humidity, light exposure, and air circulation within the greenhouse space. The unit employs advanced sensors and automated control systems to monitor and adjust these parameters in real-time, ensuring plants receive consistent growing conditions regardless of external weather changes. The technology incorporates energy-efficient heating and cooling systems, humidity management through precision ventilation, and smart lighting controls that can simulate natural daylight patterns. The system's core functionality includes automated climate control algorithms that can manage multiple zones within the greenhouse, allowing for different environmental conditions to be maintained simultaneously for various plant species. Additionally, the unit features water management systems that optimize irrigation schedules and maintain proper moisture levels. Modern constant environment units also come equipped with remote monitoring capabilities, allowing growers to track and adjust conditions through mobile devices or computer interfaces. This comprehensive environmental control solution proves invaluable for commercial greenhouse operations, research facilities, and advanced hobbyist growers seeking to maximize crop yields and quality throughout the year.