Industrial humidity control remains a critical challenge for manufacturing facilities, warehouses, and commercial buildings worldwide. When moisture levels exceed optimal ranges, equipment performance degrades, product quality suffers, and operational costs escalate rapidly. A rotary dehumidifier represents one of the most efficient solutions for large-scale moisture management, offering superior performance compared to traditional refrigerant-based systems. Understanding the key specifications and performance characteristics becomes essential for procurement teams evaluating these sophisticated industrial systems.

Understanding Rotary Dehumidifier Technology Fundamentals

Desiccant Wheel Operation Principles

The core component of any rotary dehumidifier system involves a continuously rotating desiccant wheel that absorbs moisture from incoming air streams. This wheel contains silica gel or molecular sieve materials arranged in honeycomb structures, maximizing surface area contact with humid air. As the wheel rotates slowly, it alternates between moisture absorption and regeneration phases, ensuring continuous dehumidification operation. The rotation speed typically ranges from six to twenty revolutions per hour, depending on system capacity and environmental conditions.

Advanced rotary dehumidifier designs incorporate multiple air stream configurations to optimize performance across varying load conditions. The process air stream carries moisture-laden air through approximately three-quarters of the wheel circumference, where desiccant materials extract water vapor effectively. Simultaneously, a heated regeneration air stream passes through the remaining wheel section, driving absorbed moisture from the desiccant materials and exhausting it outside the conditioned space.

Heat Recovery Integration Benefits

Modern rotary dehumidifier systems frequently incorporate heat recovery mechanisms to minimize energy consumption while maintaining optimal performance levels. These integrated heat exchangers capture thermal energy from the hot regeneration exhaust stream, preheating incoming process air or reducing heating requirements for desiccant regeneration. Energy recovery efficiencies can exceed seventy percent in well-designed systems, significantly reducing operational costs compared to standalone dehumidification approaches.

The heat recovery component also enables precise temperature control throughout the dehumidification process, preventing excessive heating of treated air streams. This thermal management capability proves particularly valuable in applications requiring specific temperature and humidity combinations, such as pharmaceutical manufacturing or precision electronics assembly facilities. Strategic heat exchanger placement within the rotary dehumidifier housing optimizes airflow patterns while maximizing energy transfer efficiency.

Critical Performance Specifications for Industrial Applications

Moisture Removal Capacity Requirements

Determining appropriate moisture removal capacity represents the most fundamental specification when selecting a rotary dehumidifier for industrial applications. Capacity ratings typically express performance in pounds or kilograms of water removal per hour under standard test conditions. However, actual performance varies significantly based on inlet air temperature, relative humidity levels, and desired outlet conditions. Procurement teams must evaluate capacity curves across expected operating ranges rather than relying solely on nominal ratings.

Industrial rotary dehumidifier systems often require capabilities ranging from fifty to several thousand pounds of moisture removal per hour, depending on facility size and process requirements. Large manufacturing operations may necessitate multiple units operating in parallel to achieve desired humidity control throughout expansive production areas. Proper capacity selection ensures adequate dehumidification during peak load conditions while avoiding excessive energy consumption during normal operations.

Energy Efficiency Performance Metrics

Energy efficiency calculations for rotary dehumidifier systems must account for both electrical power consumption and thermal energy requirements for desiccant regeneration. The coefficient of performance metric compares moisture removal capacity against total energy input, providing standardized efficiency comparisons between different equipment options. High-efficiency rotary dehumidifier designs achieve COP values exceeding four under optimal operating conditions, significantly outperforming refrigerant-based alternatives in low-temperature applications.

Regeneration energy requirements constitute the largest operational cost component for most rotary dehumidifier installations, typically consuming sixty to eighty percent of total system energy. Advanced units incorporate variable-speed drives, modulating heating elements, and intelligent control algorithms to optimize energy consumption based on real-time load conditions. These efficiency enhancements can reduce annual operating costs by twenty to forty percent compared to fixed-speed configurations.

Construction Quality and Durability Considerations

Desiccant Wheel Material Selection

The desiccant wheel represents the most critical component determining long-term rotary dehumidifier performance and reliability. High-quality wheels utilize structured ceramic or aluminum substrates with uniform desiccant coating application, ensuring consistent moisture absorption characteristics throughout the wheel surface. Premium desiccant materials maintain absorption capacity over extended operational periods, typically exceeding ten years before replacement becomes necessary under normal operating conditions.

Silica gel remains the most common desiccant material for general industrial applications, offering excellent moisture absorption capabilities across moderate temperature ranges. Molecular sieve desiccants provide superior performance in high-temperature applications or where extremely low humidity levels are required, though at increased material costs. The rotary dehumidifier wheel construction must withstand continuous thermal cycling between absorption and regeneration phases without degradation or structural failure.

Housing and Component Durability

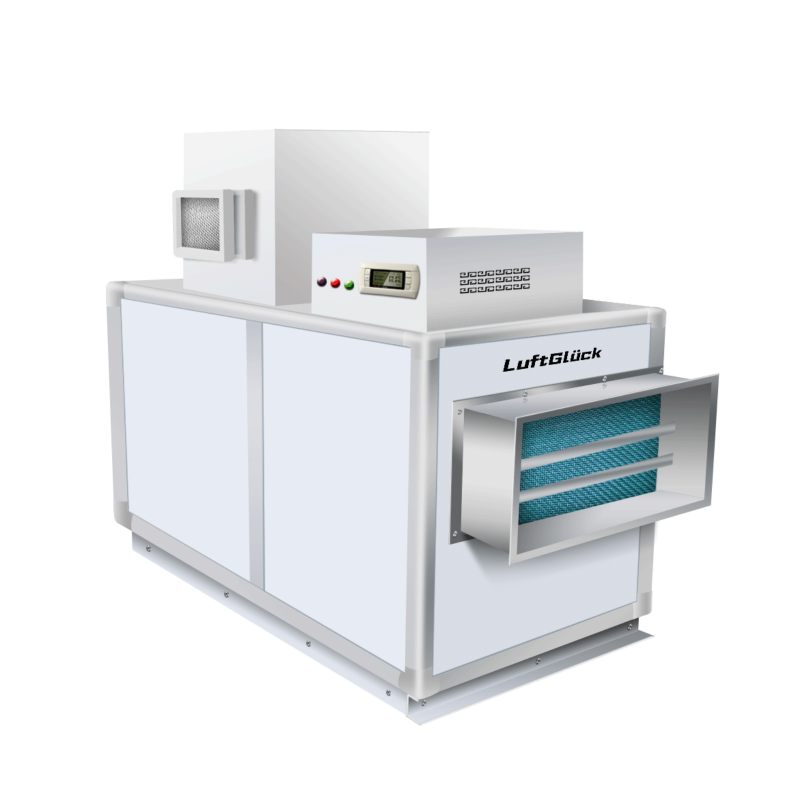

Industrial rotary dehumidifier housing construction directly impacts equipment longevity and maintenance requirements in demanding operational environments. Stainless steel or powder-coated aluminum construction provides excellent corrosion resistance while maintaining structural integrity under continuous operation. Insulation quality affects both energy efficiency and external surface temperatures, with high-density mineral wool or polyurethane foam providing optimal thermal performance.

Access panels and maintenance features significantly influence total cost of ownership for rotary dehumidifier systems throughout their operational lifespan. Well-designed units incorporate removable panels for filter replacement, wheel inspection, and component servicing without extensive system disassembly. Bearing assemblies, drive mechanisms, and sealing systems require periodic maintenance, making accessibility a crucial factor in equipment selection decisions.

Control System Integration and Automation Features

Advanced Control Algorithm Capabilities

Sophisticated control systems distinguish premium rotary dehumidifier equipment from basic models, providing precise humidity control while optimizing energy consumption automatically. Modern controllers incorporate proportional-integral-derivative algorithms that continuously adjust regeneration heating, wheel rotation speed, and airflow rates based on inlet conditions and setpoint requirements. These intelligent control systems can maintain outlet humidity within narrow tolerance bands even during rapidly changing environmental conditions.

Integrated sensors throughout the rotary dehumidifier system monitor critical parameters including inlet and outlet temperature, relative humidity, pressure differentials, and wheel rotation speed. Advanced diagnostics capabilities enable predictive maintenance scheduling and early warning of potential component failures. Remote monitoring integration allows facility managers to track performance trends and optimize operating parameters from centralized control rooms or mobile devices.

Building Management System Integration

Seamless integration with existing building automation systems represents an essential requirement for modern rotary dehumidifier installations in commercial and industrial facilities. Standard communication protocols including BACnet, Modbus, and Ethernet connectivity enable comprehensive system monitoring and control through existing infrastructure. This integration capability allows coordinated operation with HVAC systems, reducing energy consumption while maintaining optimal indoor environmental conditions.

Programmable scheduling functions within the rotary dehumidifier control system enable automatic adjustment of operating parameters based on occupancy patterns, production schedules, or utility rate structures. Energy management features can reduce regeneration heating during peak demand periods while maintaining adequate moisture control through thermal energy storage or modified operating sequences. These intelligent control capabilities significantly enhance overall system efficiency and operational flexibility.

Installation and Maintenance Requirements

Space and Infrastructure Considerations

Proper installation planning for rotary dehumidifier systems requires careful evaluation of available space, structural support requirements, and utility connections. Industrial units typically require substantial floor space or rooftop mounting areas, with adequate clearances for maintenance access and airflow distribution. Structural loading calculations must account for equipment weight, vibration isolation requirements, and seismic considerations in applicable regions.

Electrical infrastructure requirements for rotary dehumidifier installation include both standard power connections for fans and controls, plus heating requirements for desiccant regeneration. Gas-fired regeneration systems require natural gas or propane connections, while electric heating may necessitate high-voltage electrical service upgrades. Proper exhaust ducting for regeneration air discharge must comply with local building codes and environmental regulations.

Preventive Maintenance Protocols

Establishing comprehensive maintenance protocols ensures optimal rotary dehumidifier performance throughout the equipment operational lifespan while minimizing unexpected failures and associated downtime. Regular filter replacement schedules prevent contamination of desiccant materials and maintain proper airflow distribution throughout the system. Filter intervals typically range from monthly to quarterly, depending on ambient air quality and operating hours.

Desiccant wheel inspection procedures should include visual examination for damage, coating deterioration, or contamination that could compromise moisture absorption performance. Annual or biannual wheel replacement may be necessary in harsh operating environments or applications involving chemical exposure. Bearing lubrication, belt tension adjustment, and sensor calibration represent additional routine maintenance tasks essential for reliable rotary dehumidifier operation.

Cost Analysis and Return on Investment Factors

Initial Capital Investment Considerations

Capital costs for industrial rotary dehumidifier systems vary significantly based on capacity requirements, construction materials, and control system sophistication. Entry-level units suitable for smaller applications may cost fifteen to twenty-five thousand dollars, while large-capacity systems with advanced features can exceed one hundred thousand dollars. However, total project costs must include installation, electrical connections, ductwork modifications, and commissioning services.

Financing options and equipment leasing arrangements can reduce initial cash requirements while spreading costs over the rotary dehumidifier operational lifespan. Many manufacturers offer extended warranty programs and service contracts that provide predictable maintenance costs and performance guarantees. Evaluating total cost of ownership rather than initial purchase price ensures optimal equipment selection for long-term operational success.

Operational Cost Optimization Strategies

Energy costs typically represent the largest operational expense category for rotary dehumidifier systems, making efficiency optimization a critical factor in equipment selection and operation. Time-of-use utility rates may enable significant cost reductions through scheduled operation during off-peak periods, particularly for applications with thermal storage capabilities or flexible humidity control requirements. Demand charge management through intelligent load scheduling can further reduce electrical costs.

Preventive maintenance programs minimize emergency repair costs while extending equipment lifespan and maintaining optimal rotary dehumidifier performance. Service contract arrangements with qualified technicians ensure proper maintenance execution while providing access to technical support and replacement parts. Regular performance monitoring enables early identification of efficiency degradation, allowing corrective action before significant energy penalties accumulate.

FAQ

What are the main advantages of rotary dehumidifiers compared to refrigerant-based systems

Rotary dehumidifier systems excel in low-temperature applications where refrigerant-based equipment experiences reduced efficiency or operational limitations. They can achieve extremely low humidity levels, often below ten percent relative humidity, which proves essential for pharmaceutical manufacturing, electronics production, and specialized storage applications. Additionally, rotary dehumidifiers maintain consistent performance across wide temperature ranges and can operate effectively in sub-freezing conditions where refrigerant systems would require defrost cycles.

How do I determine the appropriate capacity for my industrial application

Capacity selection for a rotary dehumidifier requires detailed analysis of moisture loads from various sources including outdoor air infiltration, process equipment, product moisture content, and personnel occupancy. Consulting with experienced engineers or equipment manufacturers helps ensure proper sizing based on peak load conditions while considering future expansion requirements. Oversized equipment increases energy consumption and capital costs, while undersized systems fail to maintain desired humidity levels during peak demand periods.

What maintenance is required to keep rotary dehumidifiers operating efficiently

Regular maintenance for rotary dehumidifier systems includes monthly filter inspections and replacements, quarterly belt tension checks, semi-annual bearing lubrication, and annual desiccant wheel evaluation. Sensor calibration should be performed annually to ensure accurate humidity control, while heat exchanger cleaning may be required based on operating environment conditions. Establishing maintenance schedules with qualified service technicians ensures proper procedures and helps identify potential issues before they impact system performance.

Can rotary dehumidifiers integrate with existing building automation systems

Modern rotary dehumidifier equipment incorporates standard communication protocols enabling seamless integration with most building automation systems. BACnet, Modbus, and Ethernet connectivity options provide comprehensive monitoring and control capabilities through existing infrastructure. This integration allows coordinated operation with HVAC systems, automated scheduling based on occupancy or production requirements, and remote monitoring capabilities for facility management teams. Proper integration reduces energy consumption while maintaining optimal environmental conditions throughout the facility.

Table of Contents

- Understanding Rotary Dehumidifier Technology Fundamentals

- Critical Performance Specifications for Industrial Applications

- Construction Quality and Durability Considerations

- Control System Integration and Automation Features

- Installation and Maintenance Requirements

- Cost Analysis and Return on Investment Factors

-

FAQ

- What are the main advantages of rotary dehumidifiers compared to refrigerant-based systems

- How do I determine the appropriate capacity for my industrial application

- What maintenance is required to keep rotary dehumidifiers operating efficiently

- Can rotary dehumidifiers integrate with existing building automation systems