Constant Temperature & Humidity, Precision Air Conditioning, High Sensitivity, Stable and Reliable JHLF

The GHLF series constant temperature and humidity machines offer various horsepower specifications to cover application spaces of different sizes. They feature precise temperature and humidity control capabilities and robust air handling performance.

- Overview

- Recommended Products

Constant Temperature and Humidity Machines: Intelligent Controllers for Precision Environments

In semiconductor wafer manufacturing, a ±0.5°C temperature fluctuation can cause lithography deviations; during biological sample storage, a ±2%RH humidity drift may compromise viability. Our constant temperature and humidity machines, built on industrial-grade standards, integrate "precision control" and "scenario adaptation" technologies to construct stable micro-environments for high-end manufacturing, scientific research, and special storage scenarios.

I. Core Technical Features: Precise Temperature-Humidity Control for Harsh Requirements

✦ Dual-dimensional Precision Control: Utilizing German Schneider temperature control components and imported humidity sensors, it typically achieves ±1°C temperature control (18-30°C range) and ±5%RH humidity adjustment. Customized models can reach ±0.5°C/±2%RH high precision (e.g., for laboratory-specific applications). Real-time dynamic monitoring of environmental parameters initiates adjustment within 10 seconds of exceeding thresholds, ensuring stability in semiconductor chip workshops and lithium battery pole piece drying.

✦ Full Operating Condition Adaptability: Supports wide-temperature operation from -10°C to 45°C, paired with R-32 (German TÜV certified)/R410A refrigerants to maintain energy efficiency in regions with significant temperature variations. For example, in northern winter laboratories, the equipment automatically activates electric heating compensation to maintain 23°C±1°C constant temperature.

II. Industrial-Grade Energy Efficiency and Durable Design

✦ 20% Energy Saving System Optimization: Equipped with rotary/fully enclosed scroll compressors (Danfoss/Hitachi brands), combined with 0.1mm hydrophilic aluminum fin coils and internally threaded copper tube heat exchange systems, energy consumption is reduced by 15%-20% compared to traditional equipment. In a 300㎡ warehouse, annual power consumption can be reduced by 12,000 kWh, while supporting waste heat recovery technology to further lower operational costs.

✦ All-metal Anti-environment Structure: The body uses electrostatically sprayed sheet metal casing, passing a 48-hour salt spray test, and can operate continuously for 3 years without failure in humid pharmaceutical warehouses or dusty workshops. Wide voltage design adapts to 220V/380V power grids to meet installation requirements in different regions.

III. Intelligent Control and Integrated Management

✦ PLC Intelligent Touch Control System: Standard with a color touchscreen, supporting free setting of temperature and humidity, real-time data display, and fault code alarm (e.g., compressor overload, sensor abnormality). The RS485 communication interface can be connected to the factory MES system for cluster monitoring of multiple units, suitable for central control needs in large electronic factories.

✦ Fully Automatic Operation Logic:After presetting parameters, it starts and stops automatically, goes into standby when target values are reached, and restarts when temperature/humidity exceeds thresholds, requiring no manual intervention. For example, in a vaccine cold storage, the equipment continuously maintains 2-8°C/RH35%-65% while uploading data to a cloud monitoring platform.

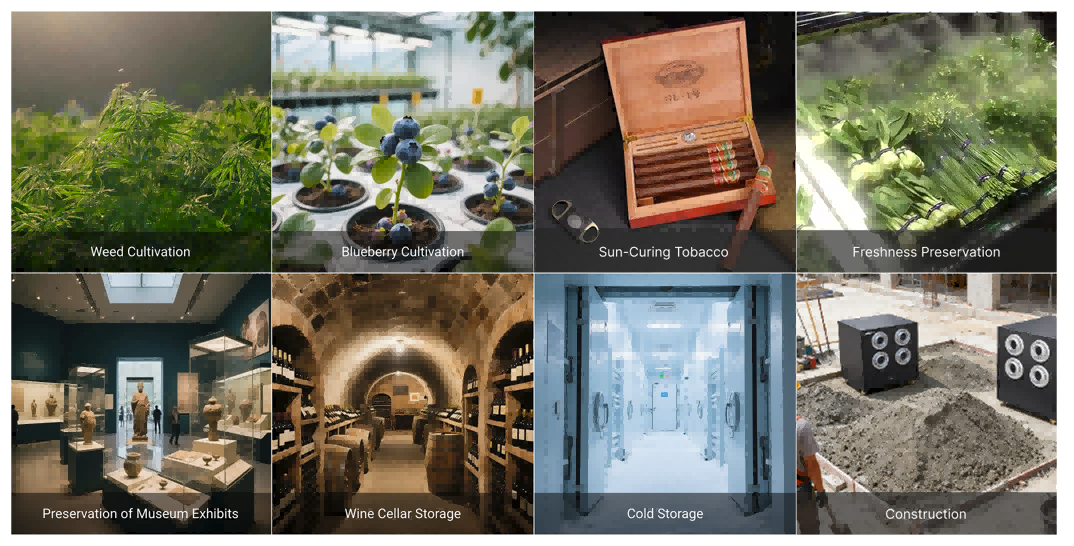

IV. Scenario-based Solutions

✦ High-end Manufacturing:Provides ultra-dry environments with dew points < -50°C for semiconductor packaging workshops to prevent chip welding moisture; maintains 25°C±0.5°C/RH45%±2% in precision optical component processing to ensure coating process accuracy.

✦ Medical and Warehousing: GSP-certified pharmaceutical warehouse models precisely control 15-25°C/RH35%-65% through electrode humidifiers and dual-cooling source designs; wine cellar applications combine explosion-proof designs to maintain 12-18°C/RH60%±5% for protecting wine aging quality.

✦ Cultural and Scientific Research: Museum heritage storage uses full stainless steel body models with HEPA filtration systems to control 20°C±1°C/RH50%±3% and prevent calligraphy/painting mildew; plant tissue culture laboratories achieve temperature/humidity fluctuations within ±0.8°C/±2%RH through customized solutions, increasing seedling survival rates to 92%.

V. Certifications and Service Guarantee

Products pass multiple certifications including 3C, CQC, CE, GS, and ISO9001, with core components (compressors, sensors) guaranteed for 1 years. The German team supports 48-hour response, providing full-chain services from "temperature-humidity simulation-energy consumption calculation-after-sales operation" for scheme design and installation.

Widely used in:

Telecommunications/IT equipments rooms

Wine cellars

Wine display cabinets

Testing laboratories

Factory Strength | CCC Certification | Carel Control Panel | Quality Assurance | Worry-Free After-Sales

Technical Specifications:

| Parameter | Details | ||||||||||

| Model No. | JHLF-03B | JHLF-05B | JHLF-09B | JHLF-12B | JHLF-20B | JHLF-30B | JHLF-40B | JHLF-50B | JHLF-60B | ||

| Applicable Area | 10-15 m² | 15-25 m² | 25-35 m² | 35-55 m² | 60-80 m² | 80-120 m² | 130-160 m² | 160-200 m² | 200-240 m² | ||

| Ceiling Height | 3 m | ||||||||||

| Horsepower | 1 HP | 2 HP | 3 HP | 5 HP | 8 HP | 10 HP | 16 HP | 20 HP | 24 HP | ||

| Air conditioning unit's overall performance | Cooling Capacity | 3.5 kW | 5 kW | 8.9 kW | 12 kW | 20 kW | 30 kW | 40 kW | 50 kW | 60 kW | |

| Heating Capacity | 2 kW | 3.5 kW | 5 kW | 7 kW | 12 kW | 18 kW | 21 kW | 28 kW | 32 kW | ||

| Airflow Volume | 550 m³/h | 1000 m³/h | 2200 m³/h | 3000 m³/h | 4200 m³/h | 5500 m³/h | 8000 m³/h | 10000 m³/h | 12000 m³/h | ||

| External Static Pressure | 50 Pa | 50 Pa | 100 Pa | 150 Pa | 200 Pa | 200 Pa | 200 Pa | 300 Pa | 300 Pa | ||

| Noise Level | 58 dB (A) | 58 dB (A) | 60 dB (A) | 62 dB (A) | 62 dB (A) | 65 dB (A) | 68 dB (A) | 70 dB (A) | 72 dB (A) | ||

| Control System | PLC Intelligent Touchscreen | ||||||||||

| Temperature Control | Range: 18-25 °C (±1° C),can also be customized | ||||||||||

| Humidity Control | Range: 45-75% RH (±5%) | ||||||||||

| Power Supply | 230V/50Hz | 380V/50Hz Three-Phase Five-Wire System | |||||||||

| Total Power Input | 5 kW | 7.2 kW | 11.2 kW | 15.5 kW | 22 kW | 32 kW | 43 kW | 53 kW | 65 kW | ||

| Refrigeration system | Compressor | Rotary Compressor | Hermetic Turbo Compressor | ||||||||

| Quantity | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | ||

| Nomial Input Power | 1.125 kW | 1.5 kW | 2.3 kW | 3.75 kW | 6 kW | 7.5 kW | 12 kW | 15 kW | 18 kW | ||

| Refrigerant | Type | R-32 / R-410A | |||||||||

| Throttling Methode | Thermal Expansion Valve | ||||||||||

| Auxiliary Electric Heating | Type | Electric Heating | |||||||||

| Power | 2 kW | 3.5 kW | 5 kW | 7 kW | 12 kW | 18 kW | 21 kW | 28 kW | 32 kW | ||

| Humidifier | Type | Electrode Humidifier / Electric Heating Humidifier | |||||||||

| Regeneration Fan | Humidification Capacity | 2 kg/h | 2 kg/h | 4 kg/h | 8 kg/h | 4 kg/h | 8 kg/h | 8 kg/h | 15 kg/h | 15 kg/h | |

| Power | 1.5 kW | 1.5 kW | 3 kW | 3 kW | 3 kW | 6 kW | 6 kW | 11.25 kW | 11.25 kW | ||

| Indoor Unit | Dimensions | Length | Customized | ||||||||

| Width | |||||||||||

| Height | |||||||||||

| Outdoor Unit | Dimensions | Length | 857 mm | 857 mm | 1093 mm | 1193 mm | 788 mm | 1193 mm | 788 mm | 888 mm | 888 mm |

| Width | 445 mm | 445 mm | 456 mm | 456 mm | 788 mm | 456 mm | 788 mm | 835 mm | 838 mm | ||

| Height | 616 mm | 616 mm | 813 mm | 963 mm | 925 mm | 963 mm | 925 mm | 1085 mm | 1085 mm | ||

| Number of Units | 1 | 2 | |||||||||

| Connection Pipe Diameter | High-pressure Pipe | 9.52 mm | 9.52 mm | 12.7 mm | 12.7 mm | 16 mm | 12.7 mm*2 | 16 mm*2 | 16 mm*2 | 16 mm*2 | |

| Low-pressure Pipe | 12.7 mm | 12.7 mm | 19 mm | 19 mm | 19 mm | 19 mm*2 | 19 mm*2 | 28 mm*2 | 28 mm*2 | ||

*Product specifications may be modified without notice to improve performance.

Who we are

Ranking among China's Top 5 air humidity brands with products exported to over 50 countries. The 50,000㎡ modern factory boasts full production capabilities, supported by a professional team of 258 experts and 3 advanced testing laboratories to ensure quality, efficiency, and on-time delivery. We offer flexible one-stop services, including OEM, ODM, JDM, and more.

Our international brand, LuftGlück (German for "Joy of Air"), specializes in providing tailored humidity and temperature management solutions for key sectors such as agriculture (including medical cannabis), construction environments, food processing, and high-tech industries. With core strengths in powerful dehumidification, energy efficiency, and ultra-quiet operation, our products are certified by 3C, CQC, CE, GS, and ISO9001, helping global clients reduce costs, enhance efficiency, and achieve sustainable development.

📞Contact Us:

Email: [email protected]

LuftGlück — Joy of Air. Made in China. Trusted Worldwide.