In the world of cigars, each one is a treasured blend of nature’s gift and human craftsmanship. From a single seed to a perfectly presented cigar, it takes over 200 meticulous processes — with the growth and treatment of the tobacco leaf being especially critical.

Tobacco leaves grow quickly. To ensure they focus their energy on leaf development rather than flowering, the buds are regularly removed by hand — a process known as “topping”. After around three months of careful nurturing, a single leaf may undergo more than 170 individual attentions before it is ready for harvest.

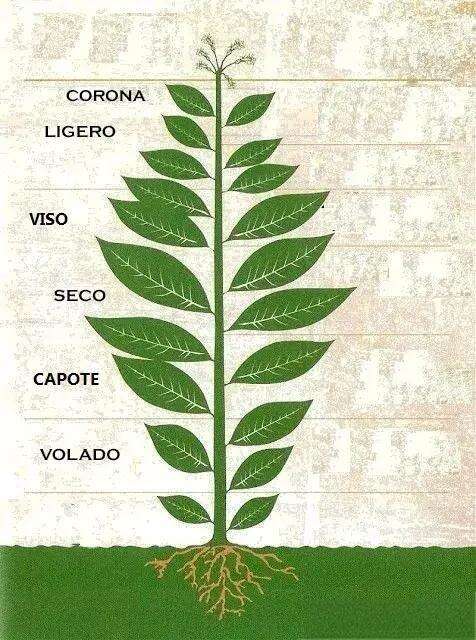

Image: Tobacco Leaf Plant

Image: Tobacco Fields

Image: Tobacco Fields

A premium cigar relies on an outstanding growing environment and high-quality leaf. The cultivation of tobacco mainly involves seedling cultivation, field growing, and harvesting — each step requiring the skilled hands and expertise of experienced farmers.

Image: The Source of Leaf Quality: Essential Pre-Processing Techniques

Once harvested, the tobacco leaves go through multiple rigorous stages including curing, sorting, fermentation, re-sorting, resting, and stemming. Among these, the pre-processing techniques are the cornerstone of the leaf’s final quality.

Image: Sun-Curing Tobacco

Image: Sun-Curing Tobacco

After harvest, the leaves are transported to specialised sun-curing warehouses. Freshly picked leaves — around 100 per row — are strung onto ropes and hung approximately 3 metres beneath the wooden roof of the warehouse. Over 45 to 60 days of natural air-drying, they gradually turn from green to golden brown, after which they are sorted by leaf position and bundled for the next stage.

Beyond this point, the handling of the leaves requires the expertise of professional tobacco companies or cigar manufacturers. This is where the LuftGlück dehumidifier comes into play — precisely regulating the temperature and humidity within the curing warehouses and subsequent processing environments. It prevents issues such as mould or uneven drying caused by environmental fluctuations, ensuring that every leaf remains in optimal condition during natural sun-curing and initial drying. This lays a solid foundation for the crucial fermentation stages ahead.

Next, the leaves enter the vital two-stage fermentation process. Fermentation not only helps reduce unwanted elements such as acidity, tar, and nicotine, but also refines the leaves through continuous sorting and grading. This ensures that the finest leaves are matched with high-end cigar profiles, contributing to a richer, more balanced aroma in the final product.

Image: Tobacco Leaf Fermentation

Image: Tobacco Leaf Fermentation

Initially, the leaves are stacked about 1 metre high, covered with coarse linen, and left to ferment naturally through microbial activity for 35 to 40 days. During this time, the LuftGlück dehumidifier actively monitors and adjusts the ambient humidity, preventing mould caused by excessive heat and moisture, and ensuring the leaves uniformly develop into a consistent, rich brown colour.

The leaves are then transferred to square boxes lined with palm leaves for preliminary grading, where skilled workers meticulously sort them by colour, shape, and structure. At this stage, the leaves are lightly moistened (premium wrapper leaves often use a mix akin to cocktail water or tobacco extract, while filler leaves typically use plain water) to facilitate further processing. Damaged leaves are downgraded for use in cigarettes, filler, or machine-made cigars, while the highest-quality leaves continue to the next phase.

Image: Barrel Fermentation

Image: Barrel Fermentation

In the second fermentation stage, the leaves are piled up to nearly 2 metres high in a dark chamber. Temperature-control boxes are placed within the pile to monitor the core temperature. If it exceeds 43°C, workers will turn the pile to ensure even fermentation. Throughout this process, the LuftGlück dehumidifier continuously optimises the temperature and humidity, preventing thermal spikes that could compromise fermentation quality. This fosters a more mellow, tightly structured leaf with enhanced flavour complexity.

After the second fermentation, the leaves become smooth and fully matured. They are then packed into square bales and may be transferred to cigar factories, where they are stored in climate-controlled warehouses for ageing — often for 2 to 5 years or even longer. This extended period allows time to impart a deeper, more rounded character to the leaf.

From field to factory, from natural curing to precision fermentation, every leaf is nurtured under the most suitable conditions. The LuftGlück dehumidifier, with its expert moisture-control technology, quietly safeguards each critical stage of leaf processing — providing a reliable foundation for the consistency and excellence of premium cigar tobacco.

For this reason, the creation of a single cigar is far more than just the sum of its craftsmanship. It is a harmonious collaboration of time, nature, and technology. Its value lies not only in its complex and unique flavour profile, but also in the passion, dedication, and artistry infused into every step of its making. That is why cigars are often mentioned alongside fine wines, brandy, and single malt whiskies — all treasures born of time-honoured refinement and the pursuit of sensory excellence.

Copyright © 2026 China Glory & Achievement Suzhou Technology Co., Ltd. All rights reserved.